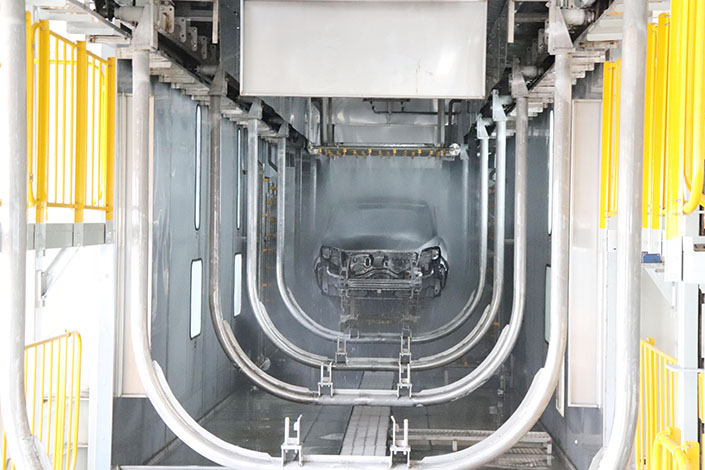

Spray type pretreatment production line

Coating pretreatment inosanganisira degreasing (degreasing), kubvisa ngura, phosphating zvikamu zvitatu.Phosphating ndiyo yepakati link, degreasing uye kubvisa ngura ndiyo nzira yekugadzirira isati yaita phosphating, saka mukuita kwekugadzira, isu hatifanirwe kungotora phosphating basa sekutarisa, asi zvakare kutanga kubva kune zvinodiwa zvephosphating mhando, kuita basa rakanaka mukuwedzera kune. mafuta uye kubvisa ngura, kunyanya teerera kune kuwirirana pakati pavo.

Degreasing derusting

Nekuvandudzwa kweindasitiri, kuchengetedzwa kwezvakatipoteredza uye kuvandudzwa kwemamiriro ekushanda zvave kunetsekana kwevanhu.Naizvozvo, kudiwa kwekuchengetedzwa kwezvakatipoteredza kunofanirwa kuverengerwa pakusarudza vamiririri.Naizvozvo, kusarudzwa kwemumiriri wekubvisa mafuta kunoda kugadzirira kuri nyore, deconfouling kugona kwakasimba, haina sodium hydroxide, silicate, OP emulsifier uye zvimwe zvikamu zvinonetsa kuchenesa patembiricha yekamuri, nyore kugeza pakupisa kwekamuri, haina chepfu. zvinhu, hazvibudisi magasi anokuvadza, mamiriro akanaka ekushanda.Kusarudzwa kwekubvisa tsvina kunoda kuiswa kwevanokurudzira, corrosion inhibitors uye inhibitors, inogona kuvandudza kukurumidza kwekubvisa ngura, kudzivirira workpiece kubva kune-over-corrosion uye hydrogen embrittlement, inogona kudzivirira zviri nani acid fog.Kunyanya akakodzera acid mhute inhibiting, kuitika muitiro pickling asidhi mhute, ngura midziyo uye chirimwa, kwete chete kusvibisa zvakatipoteredza, uye zvinogona kukonzera zino kuora, mazino conjunctival redness, misodzi, marwadzo, yakaoma huro, chikosoro uye zvimwe zviratidzo. , saka zvinobudirira inhibit acid mhute, kwete chete kudiwa kwekuchengetedzwa kwezvakatipoteredza, kana nekuda kwehutano kune zvinodiwa nemushandi.

Kugeza mvura

Kushambidza mushure mekubviswa kwemafuta uye kubvisa ngura, kunyange zvazvo iri yenzira yekubatsira isati yapenda, inodawo kukonzera kutarisa kwakakwana.Mushure mekubviswa kwemafuta uye kubvisa ngura, pamusoro peiyo workpiece iri nyore kuomerera kune mamwe asiri-ionic surfactants uye CL-.Kana izvi zvakasara zvisina kucheneswa zvakakwana, zvinogona kukonzera phosphating firimu kuonda, mutsara urema, uye kunyange phosphating.Naizvozvo, kuti uvandudze kunaka kwekugezwa kwemvura mushure mekubviswa kwemafuta uye kubvisa ngura, zvinodikanwa kuti uende kuburikidza neakawanda rinses, maviri rinses, nguva 1-2min, uye kazhinji kutsiva mvura kuve nechokwadi chekuti PH kukosha kwemvura iri pakati pe5-7. .

Phosphating

Iyo inodaidzwa kuti phosphating, inoreva simbi workpiece mushure meine dihydrogen phosphate acid mhinduro kurapwa, kemikari reaction uye mukati mayo kuburitsa dhizaini yakagadzikana insoluble phosphate firimu, iyo firimu inonzi phosphating firimu.Chinangwa chikuru che phosphating firimu ndechekuwedzera kunamatira kwekuputira uye kuvandudza corrosion kuramba kwekupfeka.Kune nzira dzakawanda dzephosphating, zvichienderana nekupisa kwephosphating, inogona kukamurwa kuita yakakwira tembiricha phosphating (90-98 ℃), yepakati tembiricha phosphating (60-75 ℃), yakaderera tembiricha phosphating (35-55 ℃) uye yakajairika tembiricha. phosphating.

Passivation

Iyo passivation tekinoroji yephosphating firimu inoshandiswa zvakanyanya muNorth America nenyika dzeEurope.Iyo passivation tekinoroji yakavakirwa pahunhu hwephosphating firimu pachayo.Iyo phosphating firimu yakaonda, kazhinji mu 1-4G / m2, iyo yakawanda haina kupfuura 10g/m2, nzvimbo yakasununguka yepore yakakura, uye kushorwa kweiyo firimu pachayo kunogumira.Vamwe kunyangwe vari mukuwomesa pakukurumidza kweyero ngura, mushure mekuita phosphating yakavharwa kurapwa, inogona kunge iri phosphating firimu pore yakafumurwa simbi oxidation, kana kuumbwa kwepassivation layer, phosphating firimu inogona kutamba kuzadza, oxidation, kuita kuti phosphating firimu rigadzikane mumhepo. atmosphere.

Kuomesa kwefirimu yephosphating

Kuomesa firimu rephosphating kunogona kuita mabasa maviri, kune rumwe rutivi, ndiko kugadzirira nzira inotevera yekubvisa mvura pamusoro pefirimu yephosphating, kune rumwe rutivi, ndeyekuwedzera kuvandudza kupikisa kwekuora kwefirimu. mushure mekuputira.

Kugadzira mutsara wekupfekedza pretreatment mutsara, dhizaini yekugadzira inofanirwa kupedzwa isati yagadzirwa, kugadzira uye kuisirwa zvisiri-yakajairwa michina.Naizvozvo, dhizaini dhizaini ndiyo hwaro hwemutsara wekugadzira, uye nzira chaiyo uye inonzwisisika ichava nemhedzisiro yakanaka pakushanda kwekugadzira uye mhando yechigadzirwa.

Inoshandiswa kune ese marudzi eworkpiece pendi, mamwe mamodheru anogona kugadzirwa.